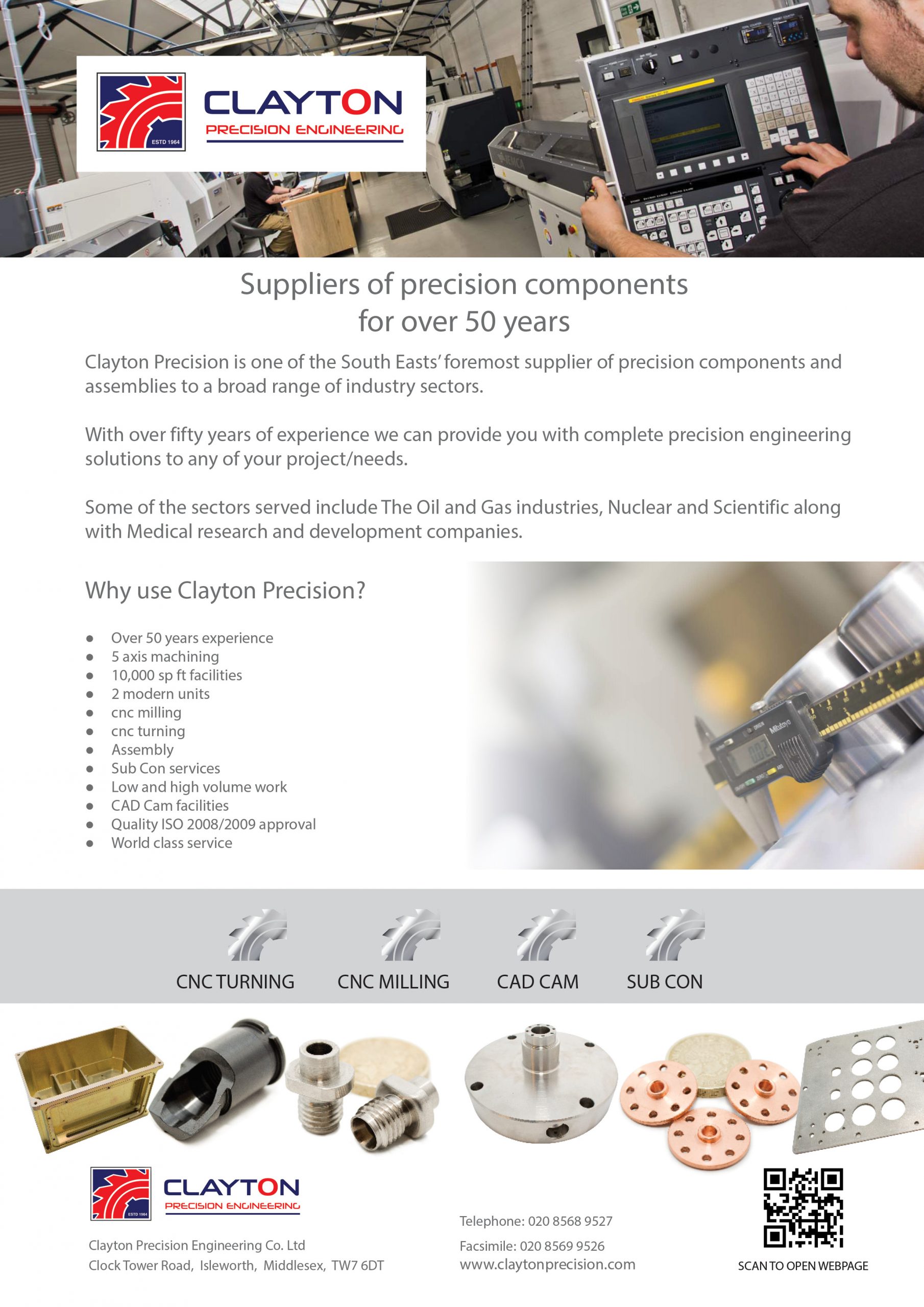

Clayton Precision Engineering & Manufacturing based in Isleworth London was established in 1970 and continues to offer CNC Milling, CNC Turning, Assembly and Sub Contract Services from 10,000sq feet of facilities which are divided across two modern units. Sectors include:- Aerospace, Oil & Gas Industries, Nuclear & Scientific as well as the Medical Research companies.

Over 50 years of precision engineering

Clayton Precision was established over 50 years ago, and it’s still a privately owned and managed company, which proudly continues to invest in the latest technology which helps us to deliver the outstanding quality & services that we are known for. We operate in various sectors which drive the world forward. The Aerospace, Oil & Gas Industries, Nuclear & Scientific as well as the Medical Research are just some of the customers we work for.

10,000sq ft facility

Based in Isleworth, West London. Clayton Precisions has over 10,000sq feet of facilities which are divided across two modern units containing the latest CNC Operating Machines. We offer components and assemblies produced to the most accurate tolerances in the most efficient and cost-effective manner. This practice is guided by our ongoing company philosophy of investing in the top current technology and people.

Skilled longterm workforce

We pride ourselves on the fast adapting and extremely reactive environment we have created here at Clayton. Complementing the modern machine shop, is a loyal workforce of highly skilled and motivated individuals, some of whom have proudly withstander a long service with us.

Support diverse projects

Clayton Precisions honours the opportunity to accept and fulfil growth within any given project. These projects from Aerospace, Gas, Oil, and Motor to Medical Research.

Loyal Customer Base

Our loyal client BOC is an example of the diverse input we offer through our services, from providing expertise and manufacturing advice across the development and prototype stages following through to the production and assembly. Clayton continues to seek and research new ways of participating within the given sectors creating a diverse range of support throughout this unprecedented times we are all faced with.

Quality & reliability

Quality and reliability are major factors within the Sectors we are supporting and we are proudly represented by AS9100 Approval.

We aim to achieve top class quality with a dedicated team who ensure every stage of manufacture is completed to its’ highest quality. We use one of the leading software for reporting results and continue to invest in training and support of our dedicated staff.

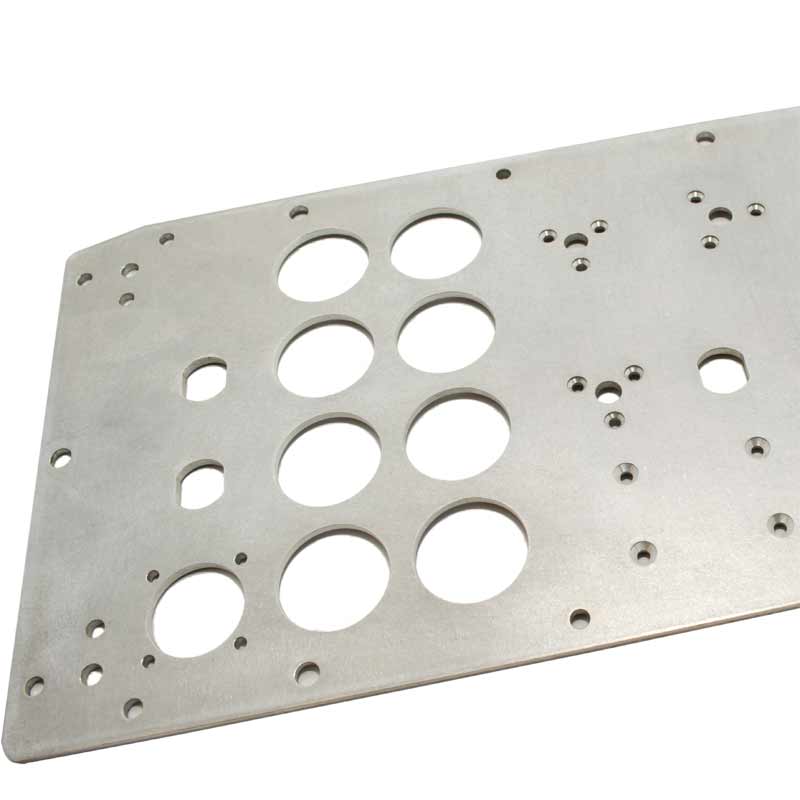

5 axis machining

We offer a broad capacity within the machine shop at Clayton’s facilities. This enables our team to produce parts from “pin head” sized in diameter through to 250 mm diameter and to 5 axis machine parts in an envelope of 750 x 500 x 500mm. Surface Finishing, heat treatment and other sub-contract operations are carried out by our approved suppliers to customer specifications.

Click below for our company downloads

Clayton Precision Engineering HAS ACHIEVED CERTIFICATION TO AS 9100 REV D

GDPR & PRIVACY POLICY

CLAYTON PRECISION LIMITED, GDPR & PRIVACY NOTICE

The implementation of the GDPR legislation starting on 25th May 2018 has made us aware of the obligations we have, regarding the data protection of your details.

Here at Clayton Precision Limited, we take your privacy seriously and will only use your personal information to administer and process your account and to provide the products and or services you have requested from us from our agreed contract. We will only process your data so that we can perform the contract or carry out a pre-contractual request from you the client.

However, from time to time we would like to contact you with future details of other [products]/ [offers]/[services]/ we provide.

We can confirm that we do not share or process your data in any way with third-parties or for any marketing purposes.

Aerospace • Nuclear • Scientific • Medical • Motor